[ad_1]

The internet is filled with pictures of polluted beaches, and people are realizing that plastic takes a long time to decompose. We have the right to say no to materials that can irritate us, and everyone deserves convenient, comfortable, and safe daily cleaning and care. As one of the top suppliers of personal care products and nonwoven wet wipes in China, SYWIPE is committed to offering eco-friendly and biodegradable wet wipes manufactured from plastic-free, high-strength spunlace nonwoven fabric for various needs.

What is spunlace nonwoven fabric?

Spunlace nonwoven, also known as hydroentangled or spunlaced nonwoven fabric, is a type of nonwoven material that is produced through a mechanical bonding process rather than chemical bonding. It is known for its excellent strength, softness, and absorbency. For wet wipes manufacturers, spunlace nonwoven fabric is the most commonly used material in wet wipes production.

The manufacturing process of spunlace nonwoven fabric typically involves the following steps:

1. Fiber blending: Different types of fibers, including natural fibers like wood pulp or cotton, and synthetic fibers like polyester or nylon, are mixed together.

2. High-pressure water jetting: The fiber blend is subjected to high-pressure water jets from a specialized nozzle. The high-pressure water flow causes the fiber bundles to mix with the water and form a spiral flow, dispersing and interweaving the fibers.

3. Web formation: The water flow pushes the fiber bundles onto a mesh forming device that contains fine holes. The fiber bundles pass through the holes and form a layer of fiber web on the other side.

4. Consolidation and drying: The fibers are bonded together and strengthened through methods such as heat pressing or other consolidation techniques. Finally, excess moisture is removed from the spunlace nonwoven fabric through drying or other drying methods.

Spunlace nonwoven fabric exhibits the following characteristics and advantages:

1. Soft and comfortable: The closely interwoven fibers of spunlace nonwoven fabric result in a soft texture that is gentle on the skin.

2. High absorbency: Due to the tight interlacing of fibers, spunlace nonwoven fabric has excellent water absorption properties, making it suitable for applications such as wet wipes and sanitary pads that require liquid absorption.

3. Good breathability: The fine pores in spunlace nonwoven fabric allow for free air circulation, providing good breathability and preventing moisture buildup.

4. High strength: Through the consolidation process, spunlace nonwoven fabric can achieve high strength and durability, making it suitable for various applications.

Thanks to its softness, absorbency, and breathability, spunlace nonwoven fabric finds extensive applications in the medical, personal care, household cleaning, and industrial sectors.

What are biodegradable wet wipes?

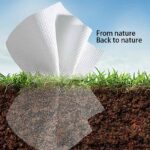

Biodegradable wet wipes are a type of wet wipes that are designed to break down and decompose naturally in the environment. They are made from materials that can undergo biodegradation, which means they can be broken down by microorganisms, enzymes, or other biological processes into simpler compounds over time.

According to BestReviews.com, 90% of wipes on the market are made from polyester or polypropylene, which can take decades to decompose in landfills. Fortunately, there is now an alternative that doesn’t sacrifice quality, convenience or the hygiene needs of families. Enter biodegradable wet wipes!

Biodegradable wet wipes are typically made from natural fibers or plant-based materials, such as sustainably sourced wood pulp, bamboo fibers, or cotton. These materials are selected for their ability to degrade and minimize environmental impact.

Some examples of biodegradable wipes include:

1. Bamboo Fiber Wipes: These wipes are made from natural bamboo fibers, which are biodegradable and renewable. Bamboo is known for its fast growth and minimal environmental impact.

2. Cotton Wipes: Wipes made from 100% cotton or organic cotton are generally biodegradable. Cotton is a natural fiber that can break down easily in the environment.

3. Cellulose Wipes: Cellulose is a plant-based fiber derived from renewable sources such as wood pulp. Cellulose wipes are typically biodegradable and compostable.

4. Viscose/Rayon Wipes: Wipes made from viscose or rayon fibers, derived from wood pulp or bamboo, are often biodegradable. However, it’s important to check if they are produced from sustainably sourced materials.

5. Plant-Based Fiber Wipes: Some wipes are made from plant-based fibers, such as cornstarch or wheat, which are biodegradable and eco-friendly.

There are various types of wipes available in the market that are biodegradable, meaning they can naturally break down and decompose over time.

What is VEOCEL Lyocell fabric?

As a wet wipes manufacturers, spunlace nonwoven fabric is the most commonly used material in wet wipe production. VEOCEL™ Lyocell and specialty viscose fibers are premium choices for personal care and hygiene products.

VEOCEL™ fibers are the preferred ingredient of leading brands focused on natural daily care methods. From forest to fiber, VEOCEL™ wood-based fibers are produced in a responsible manner, offering a naturally smooth material suitable for applications that come into direct contact with the skin. From surface, intimate, body to beauty care products, VEOCEL™ is your premium choice for everyday care.

Introducing the new product from Lenzing Group’s Lyocell fabric line, VEOCEL Lyocell. So, what is VEOCEL Lyocell fabric? VEOCEL Lyocell fabric is a fabric made from VEOCEL™ Lyocell fibers, which are produced using Lenzing’s Dry patent technology, providing exceptional water repellency. Let’s further explore the characteristics of VEOCEL Lyocell fabric.

VEOCEL™ Lyocell fibers have been redesigned to retain the advantages of their wood-based source material, offering versatility and quality. These fibers deliver the promised performance and high quality of premium products.

VEOCEL™ Lyocell fibers are produced using environmentally friendly processes. As consumers demand eco-conscious beauty, personal care, and hygiene products, our fibers serve as the cornerstone of nonwoven fabrics, caring not only for consumers and their families but also for the planet.

VEOCEL™ viscose fibers originate from wood and are capable of absorbing and retaining liquids. VEOCEL™ fibers are clean, safe, and suitable for products that come into contact with the skin—from baby wipes, body wipes, and industrial wipes to adult and feminine hygiene products, baby diapers, and other dry and wet wipes.

VEOCEL™ viscose fibers produced with Care technology are responsibly produced viscose fibers, with minimal environmental impact due to reduced carbon emissions and water usage.

VEOCEL™ viscose fibers produced with Care technology have been awarded the European Eco-Label*, an excellent environmental label that certifies products and services meeting high environmental standards throughout their lifecycle, from raw material extraction to production and disposal.

Excerpted from the official website article of VEOCEL™ https://www.veocel.com

The standout feature of VEOCEL Lyocell fabric is that it’s the first cellulose fabric with inherent water-repellent properties. Most water-repellent fabrics on the market are petroleum-based synthetics like polyester, which have significant environmental drawbacks. In contrast, VEOCEL Lyocell fabric, innovatively developed by Lenzing Group, exhibits exceptional water repellency while being biodegradable and compostable, providing an eco-friendly and sustainable plant-based alternative to synthetic materials that aligns with the consumer demand for ingredient transparency.

Additionally, VEOCEL Lyocell fabric boasts high wet strength and excellent disintegration performance due to its use of eco-disperse technology. It finds broad applications in various wet-laid nonwoven processes, typically with a blend ratio of 20% to 40% VEOCEL Lyocell fibers. The inherent high wet strength of Lyocell enables its practical versatility, and its fiber length of 8 to 12 millimeters ensures relatively quick disintegration. For instance, a nonwoven fabric comprising 20% novel Veocel Lyocell fibers and 80% wood pulp can achieve over 90% disintegration in just 30 minutes, surpassing the benchmark speed set by the INDA/EDANA FG502 disintegration test and not compromising sewage infrastructure.

Lastly, VEOCEL Lyocell fabric follows the sustainable closed-loop production process of Lyocell fibers, where over 99% of solvents are recovered and reused. The fabric has a naturally smooth texture, offering enhanced comfort and softness, making it suitable even for sensitive skin.

With its outstanding characteristics, VEOCEL Lyocell fabric has immense potential as a blend material in nonwoven products such as wipes, baby wipes, facial cleansing wipes, flushable wipes, general-purpose wipes, intimate wipes, feminine hygiene products, baby diapers, and adult diapers. It may also provide a solution to the inadequate water resistance in woven apparel fabrics.

Related articles:

Sywipe seizes every opportunity to use high-quality resources, including peer-reviewed research, to support the facts in our article.

Learn more about our factory and how to keep the content accurate, reliable, and trustworthy.

-

How to Know Flushable Biodegradable Wipes? >>

-

What is the Difference between Bamboo Pulp Paper and Wood Pulp Paper? >>

[ad_2]

Source link